General

What are The Iron Anvil's Operating hours?

The Iron Anvil operates between 8:00am and 4:30pm, during normal weekly business days (Monday - Friday). We are not working on standard Federal holidays.

What are the best ways to find out the status of my project?

The best ways to get up-to-date information on your project are:

- Call the main office: (801) 466-2053

- Send an email to: sales@ironanvil.net

- Call Vern directly: (801) 414-4766

- Contact Secretary: Julia@ironanvil.net

Where is The Iron Anvil located?

The Iron Anvil is located at 1601 So. Jefferson St., Salt Lake City Utah. This is about 140 West. The front entrance is actually along Harris Ave., which is the cross-street to Jefferson Street. We operate The Iron Anvil on the south-east corner that intersects Harris avenue and Jefferson St.

From Park City and East Side:

Take the I-80 and head west. Get off at State Street. Head north to 1700 South. Turn left, heading west to Jefferson St. Turn right onto Jefferson St, heading north. The Iron Anvil will be on the right (east) side. Parking is found on Harris Ave., at the intersection of Jefferson St.

From the I-15:

Whether you are coming from the north or south along the I-15, it seems that the quickest route to The Iron Anvil would be to exit at 1300 West. Head east, passing the TRAX line until you reach West Temple. Derk's Field (formerly the Franklin Covey Field), is found on the south-east corner. It is here that you want to head south along West Temple, driving almost to 1700 South. Turn right (west) onto Harris Ave. On this corner, intersecting West Temple and Harris Ave., on the north-west side, is the small local People's Freeway Park. Drive west along Harris avenue several more feet. On the south side of Harris avenue, you will find The Iron Anvil.

Paint

Powder Coat versus Wet Coat?

Powder Coat

- Pro- Durable, good color retention. Life-span- 1 yr to unsure. Applied electrostatically.

- Con- If the paint fails you have to take the product back to the powder coat company. They must sand blast off all the paint and start over. The removal and reinstall is not covered under warranty. Applied in powder form and does not like sharp corner or cracks and crevices.

- Can you repaint powder coat? Yes, you must sand the surface to create a profile for the paint to stick, clean surface and paint. Wet coat might not weather the same as the powder coat.

Wet Coat (Oil Primer) and Oil Base Top Coat

- Pro-Durable, Can be lightly sand and repaint on site. Oil paint is cleaned up with thinner. Life-span 5-15 years.

- Con- Paint has a tendency to fade with ultraviolet light of the sun. Touch up can appear a different color until the sun fades it out.

Wet Coat (Oil Primer) and Water Base Top Coat

- Pro-Durable, Can be lightly sanded and repaint on site. Water base is cleaned up with water. Paint will not fade in the sun. Life-span 5-20 years.

- Con- Less durable on a hand rail with extensive use.

Powder Coat Horror Stories

Powder coat was a new process that has had a learning curve. We recommend that if you choose a powder coat, that you understand these important issues. Be sure to have the job sandblasted, powder coated prime, and powder coated finish coat. Have all the pieces bolted together at the job site. Have touch-up paint from the paint supplier or have a custom mix that is matched for color and sheen. Realize that if the paint fails you will have to take the job back to the paint company; and they will have to sand blast off all the paint and start over. Blasting off powder coat paint is expensive due to powder coat paint being very hard.

- We powder coated our first job for Jim Dixon around a pool. We were told by the powder coat company that cold-roll steel, which did not have mill scale, was the best to use for this job. The job looked great for only the first week. After that, all four corners of the steel began to rust. We were told that the paint, when it dried, shrunk and pulled away from the corners. We were told that we should’ve used a round corner material because of the shrinking. They told us to bring the fence back to them and they could try again. However, we could not remove the fence. Instead, we had to repaint by hand on site the whole fence around the pool. Because of powder coat’s problems with sharp corners and edges, it is very difficult to recommend powder coat on beautifully ornate and complex iron designs.

- Our second job using the powder coat procedure was for Fors Golf Course. They insisted that they wanted powder coat. We advised them that we had not had good performance with powder-coat finishes. We used pipe for the rail and core drill and set the railing into the concrete patio. After four (4) months, they called us to come fix the rusting problems. We still have a piece of the pipe from this job showing the failure of powder coating. The water migrated under the surface and rusted the pipe. The paint came off in large layers. We had to cut the rail off and take it back to a different powder coat company. They sandblasted the rust off, and re-powder-coated the rail. Then we welded the rail back into place. Finally, we touched up the rail with custom-mix color and sheen from an automotive paint supply company.

- Another job using the powder coat process was a spiral staircase and pipe rail in Bountiful, Utah. The pipe rail has begun to rust. The spiral steps are rusting. The water has migrated under the paint. I can pull large sections of paint off the treads, thereby leaving a rusty tread. The owners are sanding down the pipe rail and repainting it. They have not as yet sanded and painted the spiral staircase, which is still deteriorating.

- On another spiral staircase project where the treads were powder coated, the paint was so thin that the rust started to build. We had to sand the tread out and repaint.

Comparison of Oil-base paint and Water-base paint

In 1992, we installed a fence around the Chateau on the Green Condos, near the Salt Lake City Zoo. The Chateau contractor requested an oil primer and an oil-base finish coat custom color. In that same year, we installed 100 feet of fence and two driveway gates on the Wilson’s home located at 7200 S. and 1300 W. On the Wilson’s property, we painted with Valley Paint products an oil primer and a water-base finish.

Only two (2) years later, the Chateau on the Green condo’s manager called and asked what they could do about their fence looking like it was 50 years old. My suggestions were to either re-prime and paint with a water base, or repaint it with another coat of oil paint.

In comparison, eight (8) years later, the Wilson’s fence still looked great, because they used a water-base finish. In 2002, the Wilson’s built town homes on the same property where we built their iron fences; and the color of the original iron fence was not matching the town home color scheme. We did not have to repaint them. But to make the town homes more appealing, we removed the panels and repainted them with a different water-base color. The City of West Jordan also required us to install another 100 ft of the same style of iron fence. We painted all the new fence using the same procedure: oil primer and water-base finish. This procedure was also applied to all of the iron deck railings, entrance rails, hand rails, wall scrolls, and light poles on the project.

You can visit the Milky Hollow project today (April 2013) and see that the iron fences, iron railings, and other iron work still look great.

How to make an order

Options

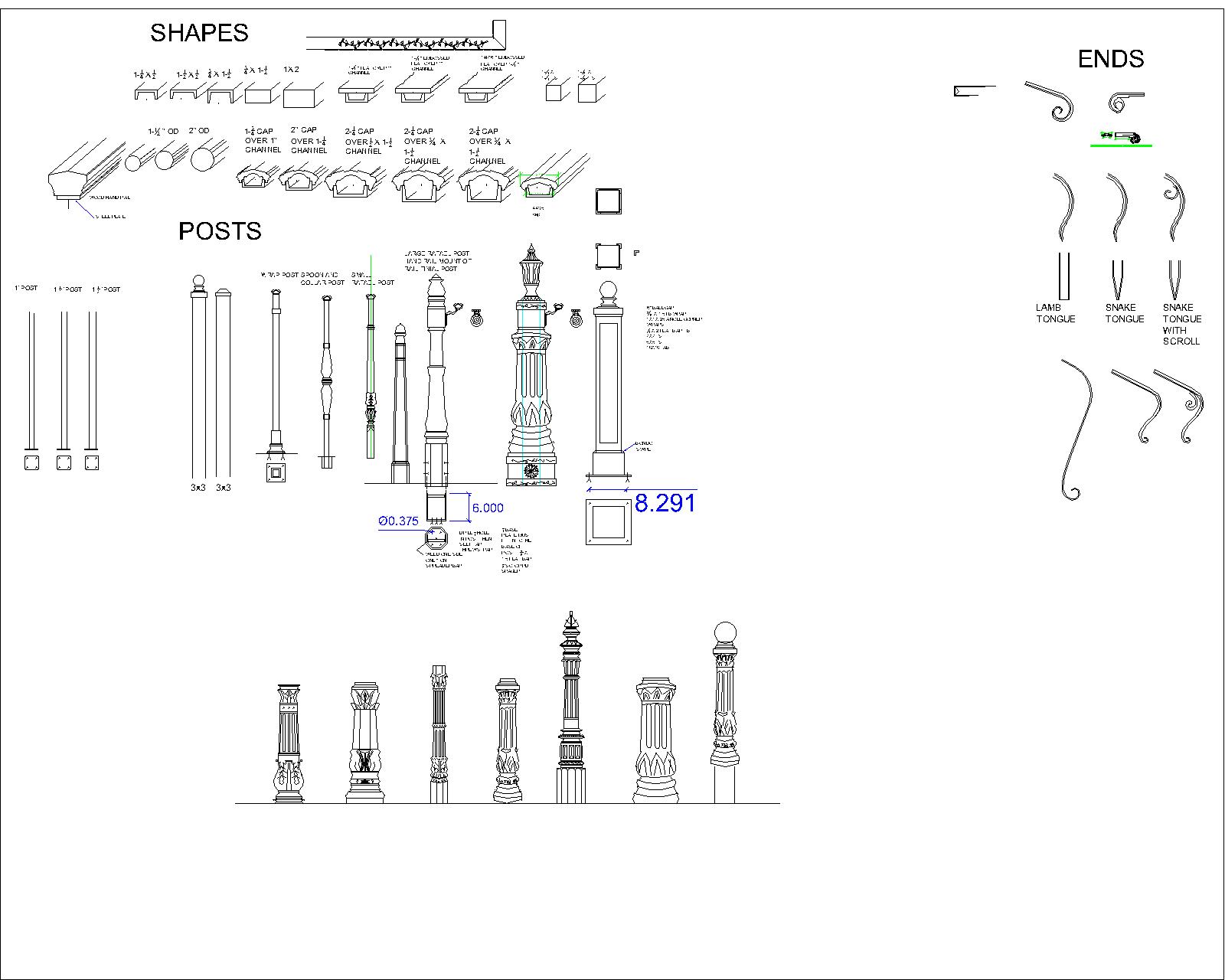

There are many things to think about when placing an order. What size of pickets do I want? Do I want a molded cap or a channel top grip? Should I have an end post or scroll? Many of these details can increase the price exponentially. Some can completely change how the rail looks. Why pay for 3/4" pickets when 1/2" pickets will look better while retaining structural integrity? Keep in mind the more precise you are with what you are ordering then the faster your bid will be completed. If you still don't know what you want then refer to one of our previously completed jobs. Product numbers should be under each photo in the gallery.